主营:欧姆龙,三菱,安川,Pro-face

主营:欧姆龙,三菱,安川,Pro-face

外观缺陷视觉检测的原理是基于光学特性照射到产品表面反射的差异来判断的。例如,当光均匀垂直射入产品表面时,如果产品表面没有任何瑕疵缺陷,反射回来的方向就不会发生改变,机器视觉所呈现到的光也是均匀的;当产品表面含有瑕疵缺陷时,出射的光线就会发生变化,所探测到的图像也要随之改变。由于缺陷的存在,在其周围就发生了应力集中及变形,在图像中也容易观察。

The principle of visual inspection of appearance defects is based on the difference of reflection of optical properties on the surface of products. For example, if there are no defects and defects on the product surface, the reflected direction will not change, and the light presented by machine vision will be uniform; when the product surface contains defects and defects, the emitted light will change, and the detected image will also change. Because of the existence of the defect, stress concentration and deformation occurred around it, and it is easy to observe in the image.

外观缺陷视觉检测系统中,图像处理和分析算法是重要的内容,通常的流程包括图像的预处理、目标区域的分割、特征提取和选择及缺陷的识别分类。每个处理流程都出现了大量的算法,这些算法各有优缺点和其适应范围。如何提高算法的准确性、执行效率、实时性和鲁棒性,一直是研究者们努力的方向。

Image processing and analysis algorithm is an important content in the visual inspection system of appearance defects. The usual process includes image preprocessing, target region segmentation, feature extraction and selection, and defect recognition and classification. There are a large number of algorithms in each process, each of which has its own advantages and disadvantages and its scope of application. How to improve the accuracy, efficiency, real-time and robustness of the algorithm has been the direction of researchers.

外观缺陷视觉检测设备特点:

Features of visual inspection equipment for appearance defects:

1.高速相机和处理技术能够对瑕疵进行快速侦测、分类、显示、剔除等;

1. High speed camera and processing technology can quickly detect, classify, display and eliminate defects;

2.优良的光学配备用于紧缺的瑕疵检测,甚至是低对比度的瑕疵;

2. Excellent optical equipment is used for defect detection, even low contrast defects;

3.智能分类软件:瑕疵根据来源被精确的分类到各个目录中;

3. Intelligent classification software: defects are accurately classified into various categories according to their sources;

4.信息准确,实时,可靠

4. The information is accurate, real-time and reliable

5.操作简单方便,无须深入学习即可瑕疵检测系统;

5. The operation is simple and convenient, and the defect detection system can be realized without in-depth study;

6.加快生产速度,实现局部全检;

6. Speed up the production speed and realize partial full inspection;

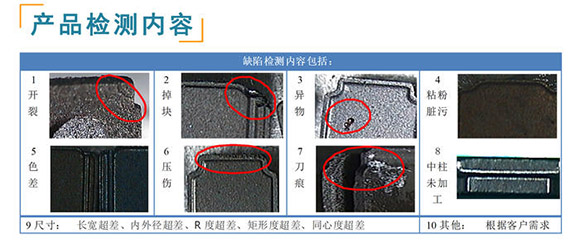

不同产品的表面缺陷有着不同的定义和类型,一般而言表面缺陷是产品表面局部物理或化学性质不均匀的区域,如金属表面的划痕、斑点、孔洞,纸张表面的色差、压痕,玻璃等非金属表面的夹杂、破损、污点,等等。

There are different definitions and types of surface defects for different products. Generally speaking, surface defects are areas with uneven physical or chemical properties on the surface of products, such as scratches, spots, holes on metal surface, color difference and indentation on paper surface, inclusion, damage and stain on glass and other non-metallic surfaces.

外观视觉检测系统的工作原理是:当产品表面含有瑕疵缺陷时,若遇到光透射型缺陷(如裂纹、气泡等),光线在该缺陷位置会发生折射,光的强度比周围的要大,因而相机靶面上探测到的光也相应增强;若遇到光吸收型(如砂粒等)杂质,则该缺陷位置的光会变弱,相机靶面上探测到的光比周围的光要弱。

The working principle of the visual inspection system for appearance is: when there are defects on the surface of the product, if the light transmission type defects (such as cracks, bubbles, etc.) are encountered, the light at the defect position will be refracted, and the light intensity will be greater than that around, so the light detected on the camera target surface will be correspondingly enhanced; if the light absorption type (such as sand and other) impurities are encountered, the light at the defect position will become weak and the phase will be weak The light detected on the target surface is weaker than the surrounding light.

机器视觉是一种无接触、无损伤的自动检测技术,是实现设备自动化、智能化和精密控制的有效手段,具有安全可靠、光谱响应范围宽、可在恶劣环境下长时间工作和生产效率高等突出优点。

Machine vision is a non-contact, non-destructive automatic detection technology. It is an effective means to realize the automation, intelligence and precision control of equipment. It has the outstanding advantages of safety and reliability, wide spectral response range, long-time work in harsh environment and high production efficiency.

外观缺陷不仅影响产品的美观和舒适度,还会对其使用性能带来不良的影响,由此可见外观缺陷视觉检测设备对于企业的重要性。

Appearance defects not only affect the beauty and comfort of products, but also have adverse effects on their performance. Therefore, it can be seen that the visual inspection equipment for appearance defects is of great importance to enterprises.

本文转载自山东红宝自动化官网,源文地址:http://www.hongbaozdh.com/news/74.html

【视觉龙】龙睿智能相机在螺丝机领域的应用

以往一般的厂家都是使用手工来打螺丝,但手工放置螺丝和对准螺丝头部仍需要占用大量的工作时间和精力,因此整体效率慢,而且人工操作极易出错,导致产品出厂质量良莠不齐,存在诸多弊端,造成生产损失。视觉龙推出

【视觉龙】龙睿智能相机在螺丝机领域的应用

以往一般的厂家都是使用手工来打螺丝,但手工放置螺丝和对准螺丝头部仍需要占用大量的工作时间和精力,因此整体效率慢,而且人工操作极易出错,导致产品出厂质量良莠不齐,存在诸多弊端,造成生产损失。视觉龙推出

嵌入式工控机助力机器视觉在工业中创新发展

本期上海研强小编给大家分享的是嵌入式工控机助力机器视觉在工业中创新发展,希望看完本篇文章您能对嵌入式工控机有一个全新的认识!如今,人工智能在我国发展迅猛, 随着新一代信息科技的成熟落地被越来越多的引

嵌入式工控机助力机器视觉在工业中创新发展

本期上海研强小编给大家分享的是嵌入式工控机助力机器视觉在工业中创新发展,希望看完本篇文章您能对嵌入式工控机有一个全新的认识!如今,人工智能在我国发展迅猛, 随着新一代信息科技的成熟落地被越来越多的引

基于MSER、SVM的玻璃纤维管纱毛羽检测

本文为解决玻璃纤维管纱(奶瓶纱)人工检测质量不稳定的问题,提出了一种基于最大稳定极值区域(MSER)和支持向量机(SVM)的玻璃纤维管纱毛羽检测方法。解决方案利用机器视觉技术对管纱毛羽疵点进行实时检

基于MSER、SVM的玻璃纤维管纱毛羽检测

本文为解决玻璃纤维管纱(奶瓶纱)人工检测质量不稳定的问题,提出了一种基于最大稳定极值区域(MSER)和支持向量机(SVM)的玻璃纤维管纱毛羽检测方法。解决方案利用机器视觉技术对管纱毛羽疵点进行实时检

基于机器视觉实现织物疵点自动检测

织物疵点的自动化检测是工业自动化视觉检测的一个分支,它是对织物质量进行控制和实现织物生产过程和品质检验的关键环节。本文主要概述在利用机器视觉和数字图像处理技术开发一套织物疵点自动检测系统。织物表面在

基于机器视觉实现织物疵点自动检测

织物疵点的自动化检测是工业自动化视觉检测的一个分支,它是对织物质量进行控制和实现织物生产过程和品质检验的关键环节。本文主要概述在利用机器视觉和数字图像处理技术开发一套织物疵点自动检测系统。织物表面在

河北挥发性有机物排放企业 VOCs检测报警实施方案

一、背景介绍挥发性有机物(VOCs)是形成细颗粒物(PM2.5)、臭氧(O3)等二次污染物的重要前体物,进而引发灰霾、光化学烟雾等大气环境问题。随着我国工业化和城市化的快速发展以及能源消费的持续增长

河北挥发性有机物排放企业 VOCs检测报警实施方案

一、背景介绍挥发性有机物(VOCs)是形成细颗粒物(PM2.5)、臭氧(O3)等二次污染物的重要前体物,进而引发灰霾、光化学烟雾等大气环境问题。随着我国工业化和城市化的快速发展以及能源消费的持续增长

饮用水处理口PH/ORP检测应用

饮用水处理口PH/ORP检测应用事实:水质控制对于饮用水处理中使用的原水至关重要。然而,许多城市往往没有慷慨的饮用水处理预算。这就是为什么系统运营商面临的挑战是,在遵守严格的成本计算的同时,实施清洁

饮用水处理口PH/ORP检测应用

饮用水处理口PH/ORP检测应用事实:水质控制对于饮用水处理中使用的原水至关重要。然而,许多城市往往没有慷慨的饮用水处理预算。这就是为什么系统运营商面临的挑战是,在遵守严格的成本计算的同时,实施清洁

CCD视觉检测(变压器平整度测量)

- 名称:CCD视觉测量捆包机 贴片元件共面度CCD视觉检测量捆包机- 型号:AT-CKJ340C- 品牌:艾拓/ATech- 功能特点:①适用于变压器、电感行业,贴片类元件的PIN脚平整度(平贴度

CCD视觉检测(变压器平整度测量)

- 名称:CCD视觉测量捆包机 贴片元件共面度CCD视觉检测量捆包机- 型号:AT-CKJ340C- 品牌:艾拓/ATech- 功能特点:①适用于变压器、电感行业,贴片类元件的PIN脚平整度(平贴度

套管的维护和检测

客户面临的挑战套管故障所造成的宕机、维修和工人加班,会给电力公司带来数百万美元的巨大损失。大约90%的套管故障都是由于垫圈泄漏、裂缝或密封不良导致潮气进入而引发的。潮气会引起套管绝缘性能变差,从而导

套管的维护和检测

客户面临的挑战套管故障所造成的宕机、维修和工人加班,会给电力公司带来数百万美元的巨大损失。大约90%的套管故障都是由于垫圈泄漏、裂缝或密封不良导致潮气进入而引发的。潮气会引起套管绝缘性能变差,从而导

专注服务于工控领域 7×8小时售后支持

全方位的技术支持 因为专注所以专业